Discus throw

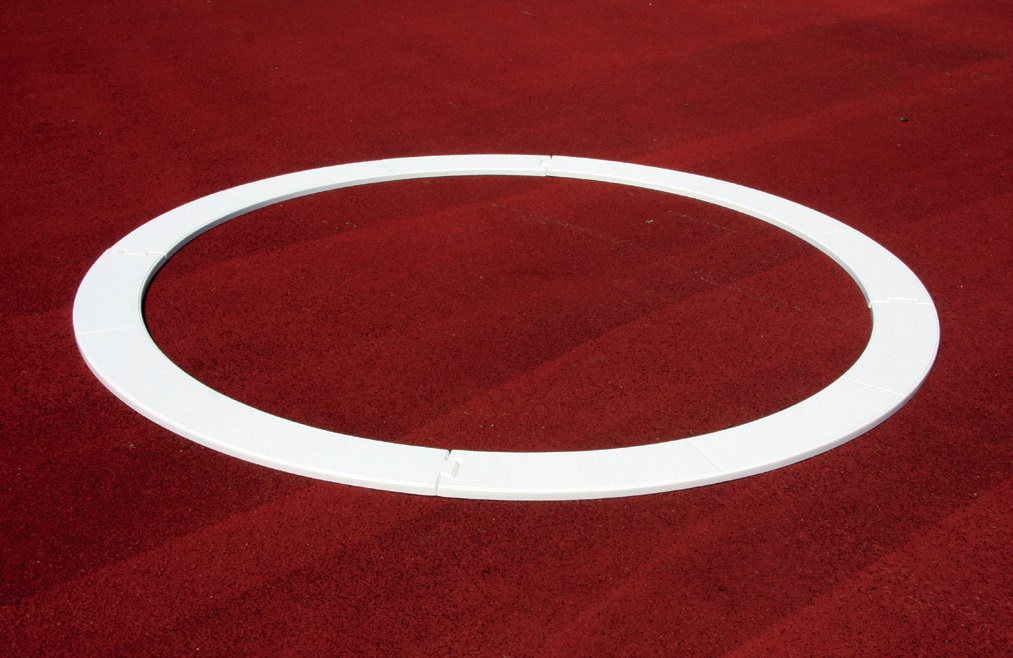

Discus throwing is an athletic discipline in which a lens-shaped discus is thrown as far as possible. The discipline was already practised in the ancient Olympic Games. The Greek sculptor Myron of Eleutherae made a famous statue of a discus thrower in the fifth century BC. A discus thrower throws a discus from a concrete discus ring with a diameter of 2.50 metres. The discus ring is surrounded by a thin, raised, metal rim of a few centimetres high. The concrete platform must be two centimetres deeper than the corresponding metal edge. The run-up to the discus throw consists of rotations that must be performed within the discus ring by the thrower. For protection, the discus ring shall always be fitted with a discus cage (also called protection cage). The cage is equipped with a safety net with an opening of several metres through which the thrower must pass. A throw is only valid if the discus lands in the throwing area, the discus has landed and the discus has left the ring in a correct manner. The pitching sector is an area that has an angle of 34.92° from the centre of the discus ring. These throwing sectors are often surrounded by stop bars. The ring must be left from the back half of the ring. The throw distance is measured from the edge of the ring to the closest impression made by the discus in the field. In most competitions, each thrower has three attempts, after which the best six or eight athletes may have three additional attempts.

Difference between discus cage and pellet cage

In discus throwing, the cage should preferably have a U-shape. The width of the opening of a discus cage must be 6 meters and is located 7 meters in front of the centre of the ring. The width of 6 metres must be formed by the gap between the left and right hanging net. The height of the net panels or of the hanging net must be at least 4 meters at the lowest point and in the 3 meters closest to the front of the cage, the height on both sides must be at least 6 meters (as of 01-01-2020).

The opening of a 6-metre ball cage must be formed by the gap between the net at the point where the doors pivot. The height of the mesh panels or of the hanging net at the back of the cage shall be at least 7 metres at the lowest point and the last 2.80 metres wide panels up to the pivot point of the movable mesh panels shall be at least 10 metres high.

If it is desired to use the same cage for the discus throw, the cage can be adapted in two ways. The simplest way is to use a 2.135 m/2.500 m concentric insert, but this means using the same surface in the cage for both bullethrowing and discus throwing. If the cage for bullethrowing is also used for discus throwing, the movable panels must be arranged so that the opening of the cage is completely free.

Bullet swing

Bullet throwing is also known as hammer throwing. Ballet swinging is an athletic discipline in which a ball, attached to a steel cable, has to be swung as far as possible. A shot put facility is always equipped with a throwing ring with a diameter of 2.135 metres (7 feet). The speed of the pendulum at release, the vertical angle at which it is thrown and its direction determine the final distance of a throw.

The ball must land within the throwing sector. If the pendulum falls outside the sector or the athlete steps outside the ring, the throw will be declared invalid. The throwing sector has an angle of 34.92°. The throwing sector is equipped with a ball cage to protect judges, spectators or other athletes.